Are you looking for an efficient, environmentally friendly method and, above all, a first-class protective coating for metal surfaces? Cataphoresis lacquers (Kathodische Tauch Lackierung), also known as KTL or e-coating – is the answer. The process applies a high-quality primer to a metal surface, and this water-based paint system offers many advantages.

For example, the painted surface has excellent corrosion resistance, good mechanical properties and high chemical resistance. The process uses trication zinc phosphating as a conversion layer and meets the high-quality requirements from industries like the automotive. A cataphoresis coating, possibly in combination with a powder coating, is suitable for most different applications and meets all current applicable requirements.

What is KTL used for?

- Parts used in or under the chassis and body

- Primer for solar panel clamps

- Brake pedals

- Fluid pipes for oil levels

- Clamps and hinges

- Roof profiles

- Trunk rollers

- Parts for electric bikes

- And much more

The process of cataphoresis painting

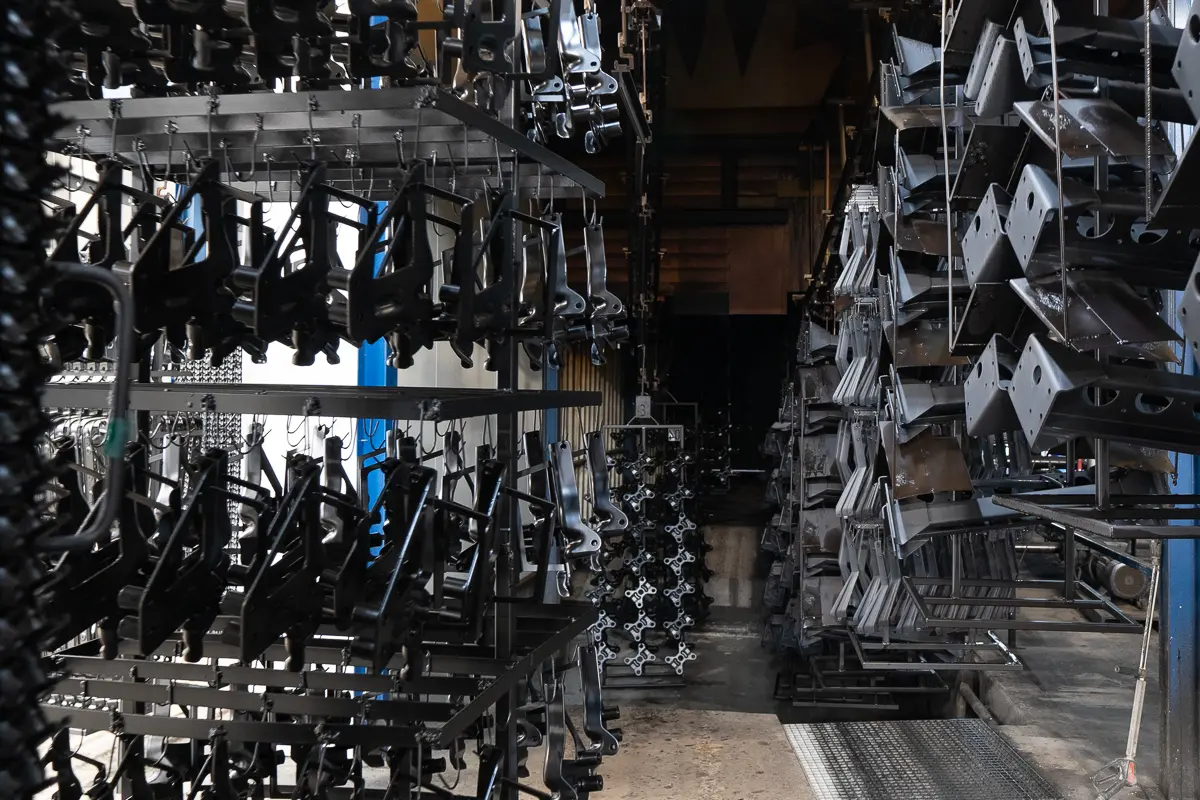

After stretching the products, we hang them on the belt to receive an optimal pre-treatment, tailored to the customer’s wishes, the final application or the manufacturer’s standard. This is how we guarantee a high-quality product right from the start. A series of pre-treatments distributed over 11 zones is automatically activated. The most critical pre-treatment steps are degreasing, rinsing, activation (zinc phosphating) and passivation. After this, the products go through a 75,000 liter lacquer bath.